PVC Recycling – A Profitable Business Opportunity

Polyvinyl Chloride is a synthetic plastic polymer that is used worldwide for various requirements. Polyvinyl Chloride is also known as PVC which is the third most produced synthetic plastic polymer in the world. PVC has a very wide range of applications and therefore its usage. PVC is known to be a durable element in plastic therefore it is highly reliable and is used in place of metals. The significant rise in the usage of PVC is also attributed to its cheap cost, easy manufacturing, transportation and maintenance. Unlike plastics, PVC’s molecules are closely bounded thus creating a very strong and reliable material. One can easily recycle PVC with the help of available machines by following recycling process.

Some Applications of PVC

PVC is known to be a reliable, durable and strong material therefore it is used in various places. Some of them are:

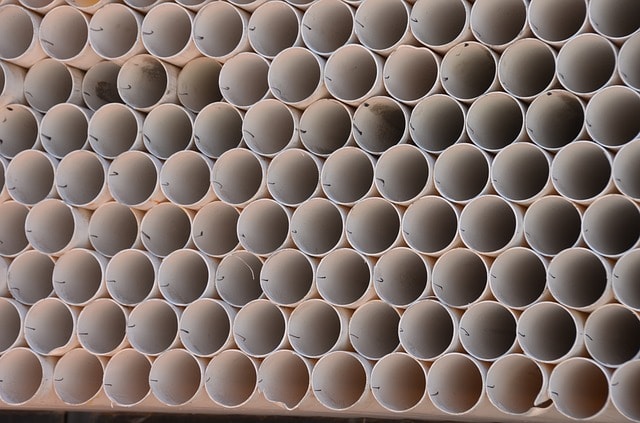

- PVC is used in the manufacturing of pipes that are basically in household requirements, plumbing, housing, etc.

- PVC is used in manufacturing construction materials like PVC sheet that is used as a shade which one can easily spot in local roadside shops.

- Electric cables also use PVC which is quite reliable to cover up the metal wire

- It is used in manufacturing various other products that are of daily use.

- It is also used in manufacturing in clothes, signs, flooring etc.

The production of PVC was 38.5 million tons in the year 2013 in which China was the largest producer of PVC followed by United States. It is estimated to rise by 2.30% by 2021.

PVC is also known to be a very toxic substance and many countries are thinking to curb its production and usage. The burning of PVC results in heavy black colored smoke which is extremely poisonous and toxic. PVC has very bad impact on the health of people who regularly use it. It was stated that PVC can even cause cancer if it is used on a regular basis.

Recycle of PVC

In the starting days usage of PVC was extremely popular because of easy production and cheap cost but with time it was discovered that dumping PVC material became very hard. Burning PVC would lead to heavy toxic smoke production. Therefore it was decided to limit the usage of PVC. Many countries also started to recycle PVC like other plastics. Now with time the recycling process has grown to many folds. Recycling PVC has now become a way of business as the product produced is sold at good price.

PVC Recycle as a Business Opportunity

PVC recycle business these days has become very common. The reason for its rise in recycle is that it offers a great price for the recycled products unlike any other recycled products. As there are abundant amount of PVC waste materials therefore one can easily setup the business and earn a good amount of money from it. The important part here is that there are many countries who offer various kinds of benefits to recycle plant owners. So if you have made your mind to open your own PVC recycling business then here is the detailed outline business plan for you to get started.

PVC Recycling Business Plan

Similar to a plastic recycling business plan, PVC recycling plan requires similar utilities. Before one starts the business one needs to conduct a feasibility analysis on your business to figure out what is required in the business, what you will get in return and how much time will it take to grow your business? Here is a detailed plan for PVC recycling business.

- Basic requirements for the recycle business

- Requirement of utilities

- Investment required

- Time required

- Other important things to care

- Return on investment

Basic Requirements for the Recycle Business:

It is important to figure out that what should be the basic things that you need to carry out your recycle business. It is also necessary to make the list and start to collect those requirements. Here are some basic requirements for your PVC recycle Business.

PVC Waste Material:

It can be PVC pipes, sheets, construction material, synthetic cloth, cable, etc. You need to network with scrap collectors, scrap sellers to buy bulk PVC waste materials from them. Give them your requirements and quantity you require. Also team up with individual scrap pickers as they will sell you waste product in low rates than the normal sellers. Buy waste on daily or weekly basis based on your requirement.

Factory for Installing Recycling Plant:

You definitely need a factory or recycle plant where you will recycle the PVC. You need to install your plant distant from the normal place as most authorities do not allow to install recycle plants amidst the city as they create pollution of different levels. You need at least a fair land area where you can keep the waste, install the machine, channel the utilities, store the products and operate your office. Don’t make it congested but open. You also need to build rooms where you will manage your work. It should be closed ventilated infra according to the norms of the authorities.

Basic Utilities for operation:

The basic amenities include water and power requirement. Recycling PVC requires fair amount of power supply and fair amount of water requirement. Make sure that the power is supplied regularly and in constant proportion as per need. Also you need to buy sufficient amount of water according to the needs and not as normal household. The added requirement is where your plant is situated. It should be at the outskirts but yet close enough to be connected with the mainstream. Transport of goods should easily be done and for that proper road infrastructure is required which you must care about.

The other point here is that you should be closer to hospital, emergency centers and police station in case of any incident.

Machine for Recycling:

A PVC recycling machine is the mandatory part of the recycling business as without the business can’t move forward. Based on what kind of PVC material you are recycling you should buy the machine. There are different kinds of PVC machine that come in market. They can be for small quantity, medium and large quantity. Based on the requirements you should but the recycling machine. Do a great amount of research over the machine when you buy it as it is quite costly.

Other Recycling Equipment

There are many more recycling equipment that one needs in the process of recycling. Containers, pipes, separator, segregator, boiler and many more. There are many modern tech equipment that makes the job much easier. Based on your requirement and budget you can buy them or rent them.

Requirement of Utilities:

Most modern days recycling plant is quite tech savvy and modern and therefore easy to operate. You can use such utilities instead of going for outdated recycling equipment. The better your equipment are the better recycling product you will get and in return the better return you will get. The other important thing here is an expert who knows how to recycle PVC. Hire a technician who is an expert in PVC recycling that can operate your plant. You will also need some labors to help the expert in recycling. Hire them as well to make the job much easier and productive.

Investment Required in PVC Recycling Business

Like any other business, a PVC Recycle also required a fair amount of capital for investment. To calculate investment you need to first figure out the money required for the above mentioned requirements. Let us start with the factory where you will install your plant. In the starting it would be better for you to rent a plant rather than purchasing it as a factory land will cost you much. If you have your own land then use it. Installation of plant will also cost you a fair amount of money like constructing rooms, water tanks, office and so on.

The next requirement is equipment. One can estimate a minimum of Rs 2 lakhs for purchasing those equipment. You can also rent them in order to save money for few months and later you can buy them when you start getting returns. The most important thing is buying the machine. In the initial days, buy a small durable machine rather than buying a large sized machine. This will save your cost. A medium sized machine will cost you around Rs 6 to Rs 15 lakhs. Do good research before you buy it as only this machine will decide your production and earning.

The rest capital requirement comes in miscellaneous requirements like water, power, expert fees, labors and many more including transportation and packing. You can also add the money required to buy scrap PVC. Add at least Rs 2 lakhs per month on them. A total of Rs 10-20 lakhs in minimum is required to open a PVC recycling Business.

Arrangement of Capital:

You can finance your business and can also take loans from banks for your business. Under Mudra Yojna run by the Central Indian government, you can get up to Rs 10 lakhs as loan while in startup scheme you can get Rs 10 lakhs to Rs 5 crore as loan. You will also get tax benefits as well in addition. One can also share the business by partnership.

Time Requirement:

Setting up your business requires at least 3 to 6 months. Only after that your business in proper would start. One can take from 9-12 months to start getting returns on the investment. Sufficient amount of return can be seen after 1 years of the commencement of business.

Things to Care:

- Network well with sellers where you will sell your recycled product.

- Contact with multiple sellers in the market from more than one state and city.

- Build different types of market so that you can get the best rate possible.

- Try to build network directly with manufacturing houses where recycled product is directly used.

- To enhance the profit, you can later on install some manufacturing plants to manufacture PVC products like PVC sheet.

- You can also enhance the quality of recycled product to get better returns.

Permissions:

Take all required permissions for operating your business. PVC generates pollution therefore clearance from all concerned authorities is necessary. Register your recycling company and pay regular taxes to build your business well. Try to register with organizations that deal with recycling to grow your clout in the business.

Return on Investment

The initial days won’t give you much return but gradually as you will build your business, start selling your recycled products, make new customers, build your market and quantity, the return will start to increase. Ensure quality in starting days to build trust in the market. Make multiple markets and try to offer something new with growing business and that will increase your production and so your return. PVC recycling market is in growing stage and will continue to grow so a steady yet firm start will give you satisfactory return.

FAQS

There are many benefits to recycling PVC. PVC can be recycled into a number of different products, including pipes, fencing, and flooring. Recycling PVC keeps it out of landfills and incinerators, where it can release harmful chemicals into the environment.

Plastic recycling businesses handle a large volume of thin plastic, such as packaging, plastic bags and film. They operate in central locations with access to transportation, allowing them to collect plastic from a wide range of businesses and consumers. To start a PVC recycling business, you will need to gather funding, acquire the proper licenses, find a good location and create a detailed business plan.

Although recycling rates of many types of plastics are on the rise, PVC recycling has lagged behind for a number of reasons. PVC debris is often sent to landfills because it is not a valuable material to many recycling facilities.

PVC is hazardous to recycle because it contains the heavy metal lead and is difficult to melt (“re-polymerize”). Therefore, plastics recyclers developed a process to re-polymerize PVC at elevated temperatures in the presence of oxygen-free radicals. Once melted, the PVC is then formed into pellets that can be molded into new plastic items.

“The best markets for recycled PVC found in consumer waste are in natural gas gathering and pipelines. They are less susceptible to heat, stress and abrasion, allowing for multiple reloads during production,” according to Bob McGill, managing partner at McGill Environmental Systems of New Jersey Inc.

PVC can be recycled and used in a variety of end markets, including construction (e.g., pipes, siding, windows, flooring), packaging (e.g., bottles, food wraps), and consumer goods (e.g., toys, credit cards).

There are a few ways to find PVC recyclers. One way is to search online directories such as Recycler’s World. Another way is to contact your local waste management agency or recycling center and inquire about PVC recycling options in your area.

Contact potential recyclers and explain what types and quantities of PVC waste you have and what you would like to do with it. Ask if they are interested in taking your material. If so, ask what they would be willing to pay per pound or ton. Some recyclers may also charge a fee for picking up the material.

PVC recycling can be challenging due to the material’s lightweight nature and the potential for contamination from other materials. It is important to keep PVC recycling separate from other types of recycling to avoid contamination. Transportation can also be a challenge, as PVC is a lightweight material that can be easily blown around by the wind.

There are a few regulatory challenges for PVC recycling. One is that PVC can be difficult to recycle because it is made with a lot of different chemicals. This can make it hard to recycle PVC without creating hazardous waste. Additionally, PVC products often contain lead, which can be harmful to the environment. Lead is considered a hazardous waste material, so recycling facilities must be careful to manage it properly.