Plastic Waste Recycling Plant – Business Plan, Profit & Cost Estimation

Plastic is a polymer known to be a non-biodegradable substance which is hazardous for the surrounding. Plastic cannot be decomposed by natural means unlike the biodegradable substances. The present world we live in is surrounded with billions of plastic products. If we recount that how many things we have used today we may easily find that most of things we have come around is made up of plastic. Thus, recycling of plastic bottles and other products provide us with huge business opportunity. Plastic recycling business is very profitable if carried out with proper business planning. In this article I will share information on how to recycle plastics in your own small scale plastic recycling plant to make profit.

Also Read:- 20 Most Profitable Recycling Businesses Available Today

Plastic is playing a huge role in our lives from usage as plastic bottles to toothbrush, mug, bucket, tub, containers, polybag, and many more. The usage of plastic has kept on rising years after years and now time has come that we cannot live without them. Plastic is a known non-biodegradable substance which means that it is not possible to break it through natural means. Plastic also a toxic substance because when it mixes in the atmosphere it causes pollution. Scientists are quite worried about the rise in plastic waste as they are unable to decompose them in comparison to the waste generation.

Generation of Plastic Waste:

Since the production of plastic in 1950s, 8.3 billion metric tons of plastic has been generated till recently. These plastics are mostly become trash after one time use. It is estimated that nearly 6.3 billion metric tons of plastic has become waste. Every year nearly 400-500 million tons of plastic waste is generated which continues to rise every year. Most of the products we use have been replaced by plastic. The shocking part in all these is that only 10-15% of total production of plastic waste is recycled.

Recycle, Reuse, And Reduce:

The 3R sums up everything on the issue of plastic waste generation. The best way to reduce plastic waste is to recycle it and reuse. There has been a rising trend seen in the recycle of plastic waste. Earlier it was took to task as a way to reduce waste and to make a use out of waste but now it has turned out to be a full-fledged business.

Many people these days are setting up plastic waste recycling plant where plastic wastes like plastic bottles, polythene, polybag, plastic containers, boxes, packets, sheets and their likes are recycled into useful products.

Plastic Waste Recycle Business Plan:

As one knows that every business requires a brief strategy and so is this business. Before we start the business to recycle plastic waste we need to first draw out a plan. Here are few objectives that are necessary to look at before we start the business of recycling plastic.

- What are the requirements for Plastic Waste Recycle Business

- Total investment required in setting up of recycling plant

- Requirement of Land or Factory

- Requirement of utilities and machines

- Collection of plastic waste

- What type of plastic waste will you recycle

- Your market after recycle

- Profit margin in plastic recycling

- Return on Investment

The above nine point sums up the whole strategy of opening a plastic waste recycle plant. We need to first analyze these points and figure out the feasibility of whether this plan would succeed or not.

Requirements for Opening a Plastic Waste Recycle Plant:

- The first basic thing you need to open up your recycle plant is a decent place. It should be at least of decent space where you can keep all the waste and waste product apart from equipment and utilities.

- The second thing required is a closed space similar to a factory but small sized room can also work. It should be of at least 200 sq. feet of size.

- The next necessary requirement is the machine by which you will recycle your plastic waste.

- Next is the plastic waste which you need to recycle. For this you can make a network of plastic waste suppliers that can supply the required amount of plastic waste.

The other requirements include a proper electric connection, generator for emergency, papers for starting a recycle business from the designated authority, permission from other selected authorities, a technical staff that can guide how to recycle the plastic, few labors, containers to store the recycled product, etc.

Land Requirement and Factory:

The demand of land depends on at what scale your plant will operate. If you are interested in small scale recycling then a 50 sq. feet room can also work but it you want large scale recycling then at least 200 to 500 sq. feet of land is required for recycling process. The land should definitely have shades, closed space, large rooms, and technical room and so on. You need to have a clean and closed space where you will keep your machine. All such closed rooms should be ventilated to avoid suffocation. A large space should be dedicated to dump plastic waste while a clean space is necessary to keep the recycled product.

Requirement of Utilities:

As you get a factory for recycling, you need proper utilities to run your factory. The foremost thing you need is a proper electric connection. You should take the required connection based on your power demand. Another important thing is proper water supply. For emergency case you should keep a proper generator. The other utilities include parts related with recycling, small tools, machines, compressor, furniture, etc.

Machines for Recycling Plastic Waste:

You need to buy the required machine for recycling your plastic waste. The plastic is first compressed and then melted using the machine. Then it is given small shapes and is then cooled down using cold water. The machine for this comes in many types. Some machines have all in one features while some come in part. Machines also depends on what type of plastic you are recycling and at what scale you are recycling. Based on this the rate of machines depend. It would be better if you choose a large scale machine that has various features.

Process involved in recycling of plastic waste:

- Collection of plastic waste and dumping

- Sorting and separation of plastic waste like PVC, ABS, LD, etc

- Grinding

- You can now supply these plastics raw material to recycling unit

- Recycling process initiated

- Compression and melting of raw materials obtained after grinding process

- Formation of pellets

- Manufacturing of new products like chair, table, bottle, etc.

After you setup your factory and have your utilities fixed. Get the plastic waste and start your recycling process. The major step involved in recycling is compressing and melting down of plastic in to a liquid. This is done in a way so that least pollution is generated. The next step involves filtering where waste residue is removed and higher quality of liquid is passed. The next step requires shaping up of the liquid plastic. Mostly they are shaped in small brick shaped or pellet shaped. They cooled down in cold water and are later put in a dry container.

Technician and Labors:

To carry all the process of recycling you definitely require a technical mind plus man force. Hire a technician who knows how to work with machines and recycle plastic. To save cost you can hire the technician for a while and after learning from him you can try it on your own. You can also take help from guides or can do a short course on it. You should also hire some labors based on your requirement to carry out the job.

Cost Involved in Setting up of plastic recycling plant:

To calculate the cost one needs to calculate the cost of all the required machines and equipment mentioned above. The first is the land whose cost depends on the location of purchase. To get the land in less cost you should buy it on outskirts of the city. Though you should ensure that you get proper facilities wherever you have purchased the land. The factory setup can easily cost you Rs 5 to 10 lakhs. The setting up of machine for recycling costs from Rs 3.5 lakhs to 35 lakhs and beyond. Don’t make cost a factor while buying the machine as it should execute the task very well based on the requirement.

Cost of other utilities will come around 1-2 lakhs per month. You can add the cost of labor and technician as well. The other requirement includes the money required to purchase plastic waste. This doesn’t costs much, around 20-30 thousand rupees per month is enough. Money required in advertisement, transportation, finishing, packing and manufacturing will add up as well. One can expect a total of 10-25 lakh rupees investment for the first time with a monthly expense of Rs 1-2 lakhs.

How to collect plastic waste for recycling:

Team up with scrap pickers and plastic waste collection houses that you will find many. Make a network with them so that they can supply you the required amount of plastic waste. Most of them will supply plastic waste to your plant while in some cases you need to transport. Make sure that your supplier uses plastic waste compressor to reduce cost involved in transportation or else it would scale up your cost requirement.

What kind of plastic you will recycle?

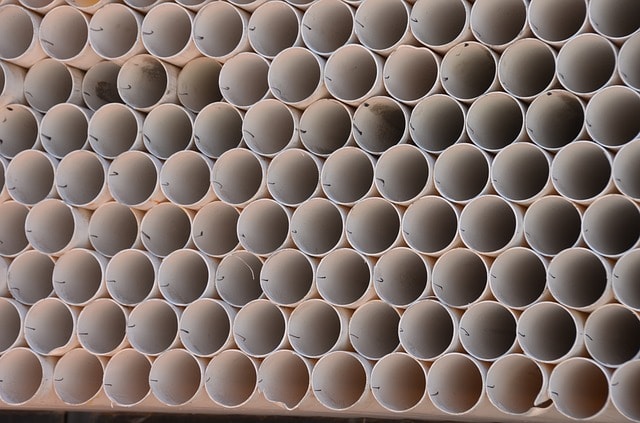

Make up your mind of what kind of plastic waste will you recycle. Try to start with small recycling plant that recycles plastic bottles, plastic sheets, polybag, small plastic containers, and their likes. You may later add PVC pipes, sheets, plastic tanks, and many others. There are different types of machine and methods required to recycle different types of plastic so choose that one that gives maximum returns.

Later on Requirements and Usage:

Based on market usage these recycled plastics are sold in the market. To make it economically more successful one can start manufacturing basic plastic products. Making polybag is one of the most successful ways to use recycled plastic. For this you just need a machine that manufactures these polybags.

Market for Recycled Plastic Waste:

The market for recycled plastic is very huge as the original non-recycled plastic is quite costlier than the recycled one. The recycled plastic lacks quality in comparison to the original fresh plastic. Your market will depend on the type of plastic and the number of times the plastic has been recycled. The first time recycled plastics are used in manufacturing high quality plastic items while the 2-3 times recycled plastics are used to manufacture plastic bottles. The lowest quality of recycled plastic is used in manufacturing use and throw plastic bottles, polythene, one time use containers, boxes and their likes.

The recycled plastic that is of the lowest grade can be sold to road departments that are using molten plastic in the place of bitumen to build roads. Molten plastic is similar to tar and is durable than bitumen. 60 kg of plastic can build a 500 meter road that is 8 meter broad. Kerala road department in India has built many such roads using recycled plastic.

Make a strong market that can offer you different rates for your recycled plastic. You can sell it to plastic product manufacturing companies, polybag makers, road transport authority and so on.

Return on Investment:

The starting return would not be much higher as the investment is high. You can take loans during investment, finance your business or can share the cost with partners. If you manage to reduce investment in factory setup then you may get starting returns. After few months of start, you can get meaningful return by selling recycled plastic.

To add the profit you can start manufacturing basic plastic products like polybags, small use and throw plastic products and so on. They have huge market. You can contact road department to take the recycled plastic of lowest order to build road as it can give you good returns.

FAQS

Some benefits of a plastic waste recycling plant include reducing the amount of plastic waste in the environment, creating new products from recycled plastic, and creating jobs for people who operate the recycling plant.

The costs associated with a plastic waste recycling plant include the cost of the facility, the cost of the equipment, the cost of the raw materials, the cost of the labor, and the cost of the waste disposal.

The process of a plastic waste recycling plant usually starts with sorting the waste by type. The most common types of plastic are PET (polyethylene terephthalate), HDPE (high-density polyethylene), and PVC (polyvinyl chloride). After the waste is sorted, it is then cleaned and shredded into small pieces. The shredded pieces are then melted and formed into pellets. The pellets are then sold to companies that use them to make new products.

The end products of a plastic waste recycling plant can vary depending on the type of plastic that is being recycled. However, common end products from a plastic waste recycling plant include plastic pellets, granules, or flakes.

The benefits of recycling plastic waste are many and varied. They include reducing the amount of waste that ends up in landfill, saving energy and resources that would be required to produce new plastic products, and helping to reduce greenhouse gas emissions.

There are a number of challenges associated with recycling plastic waste. One of the biggest challenges is that plastics are often mixed with other materials, making them difficult to recycle. Additionally, plastics can be contaminated with food or other waste, which makes them even more difficult to recycle. Finally, many plastics are not recyclable at all, which means they must be disposed of in landfill sites.

There are many benefits to using recycled plastic. Recycled plastic can be used to make new products, which reduces the need for new materials and helps to conserve resources. Additionally, using recycled plastic can help to reduce pollution and greenhouse gas emissions, as well as save energy.

There are several challenges associated with using recycled plastic. One challenge is that recycled plastic may not be as strong as virgin plastic. This means that it may not be suitable for certain applications where strength is important. Another challenge is that recycled plastic can be more expensive than virgin plastic. This is because it takes more energy and resources to recycle plastic than it does to produce virgin plastic. Finally, recycled plastic may contain impurities that can affect its quality.

The best practices for using recycled plastic depend on the type of plastic being used. For example, recycled HDPE plastic can be used to make containers, pipes, and other products that come into contact with food and beverages.